Competition Week 6

Week 13 (4/2 - 4/8)

Assembly

04/3 Monday

Retest batteries from AVR

Members check packing

Clean machine shop

Drive base electrical

Helped w new battery cart

Worked on Houston packing list

Change elevator gear ratio to 15:1

Change elevator motor mount screws

Find better way to secure motor

04/7 Friday

Inventory for backup elevator

Got new treads for proto bot swerve module wheels

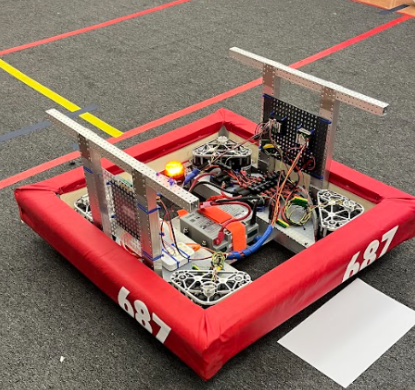

Finished assembling new bumpers for IS ME

New bumpers (red and blue)

Finished electrical for proto bot

Tested batteries

Fixed a battery lead

Packed for Houston

Cleaned electrical benches

Made and assembled smaller foldable cone nodes to fit shipping requirements

04/08 Saturday

Went to Da Vinci

Assemble (spare) elevator

Clean machine shop

Continue testing batteries

CAD

4/3

Since we have finished Cadding our robot, we have focused on meching the robot (new bumpers, fixing flaws, adding new 3D prints, etc).

4/8

After finishing the updates to our robot, we went to a practice field in order to test our robot with other teams.

Programming

This week, we switched to using velocity control on our swerve drive during autos. This allows our auto timings to be more accurate.

public void setDesiredState(SwerveModuleState state) {

if (Math.abs(state.speedMetersPerSecond) < 0.001) {

stop();

return;

}

state = SwerveModuleState.optimize(state, getState().angle);

desiredAngle = state.angle.getDegrees();

double velocity = state.speedMetersPerSecond / ModuleConstants.kDriveTicksPer100MsToMetersPerSec / ModuleConstants.kDriveMotorGearRatio;

this.desiredVelocity = velocity;

// Toggle between velocity control and percent output

if (this.velocityControl) {

driveMotor.set(ControlMode.Velocity, velocity);

} else {

double currentPercent = state.speedMetersPerSecond / SwerveDriveConstants.kPhysicalMaxSpeedMetersPerSecond;

driveMotor.set(ControlMode.PercentOutput, currentPercent);

}

double turnPower = turningController.calculate(getTurningPosition(), state.angle.getRadians());

turnMotor.set(ControlMode.PercentOutput, turnPower);

}

We also added offsets to all of our gyro axes, allowing us to zero all axes at the start of autonomous init. This should make our balancing autos more reliable.

We implemented this in Pull Request #70.

public interface Gyro extends Reportable {

/** Soft reset all axes */

public void zeroAll();

public void zeroHeading();

/** Soft reset the pitch */

public void zeroPitch();

/** Soft reset the roll */

public void zeroRoll();

/** Soft reset the heading */

public void resetHeading(double headingDegrees);

/** Soft reset the pitch */

public void resetPitch(double pitchDegrees);

/** Soft reset the roll */

public void resetRoll(double rollDegrees);

/** Set the yaw offset */

public void setOffset(double offset);

/** Set the pitch offset */

public void setPitchOffset(double offset);

/** Set the roll offset */

public void setRollOffset(double offset);

/**

* Get the heading in degrees. (CW = positive)

* @return IMU Heading in degrees.

*/

public double getHeading();

/**

* Get the pitch in degrees. (CW = positive)

* @return IMU Heading in degrees.

*/

public double getPitch();

/**

* Get the roll in degrees. (CW = positive)

* @return IMU Heading in degrees.

*/

public double getRoll();

public double getHeadingOffset();

public double getRollOffset();

public double getPitchOffset();

public Rotation2d getRotation2d();

public Rotation3d getRotation3d();

}

Our updated Gyro interface, implemented in both NavX.java and Pigeon.java